|

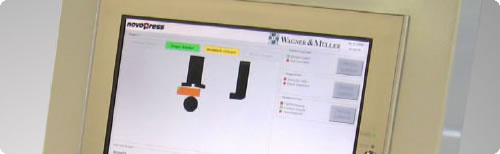

Based on an embeded Windows XP System, the BGD5 offers simple

WYSIWYG programming, with full graphical interface. No CNC

programming skills are required with even the most complicated

busbar configurations easily created / edited.

During bending operation the digital angle measurement with

full automatic spring back compensation will ensure an accuracy

of +/- 0.2 degrees from requested value. The automatic length

stop will travel up to 800mm positioning your busbar within

seconds. With an intigrated 3Ph/400V power pack minimising

cycle times to around 11 seconds for a 90 degree bend including

the spring back competnsation

Advantages at a Glance:

- Latest Windows XP technology with 12" LCD monitor

- Unmatched, full graphical WYSIWYG programming

- USB and LAN for backups and remote editing

- Digital encoder with an accuracy to 0.2 degrees

- Full automatic spring back compensation

- No trial bends, No setup time

- Digital stroke encoder for minimum cycle time

- Intigrated high performance 3Phase power pack

- Optional step and edgebending tools

- Tight U and Z bends possible

- Mobile for ease of movement within workshop

| Technical Specifications

- Incl Automatic Lentgh Stop Part 41800 |

| Depth |

900mm |

| Width |

1630mm |

| Height |

1530mm |

| Weight |

370Kg |

| Hydraulic Pressure |

200 bar max. (3000psi) |

| Max. Busbar Size |

160x13mm (6"x1/2") |

| Length Stop Travel |

800mm |

| Bending Radius Adapters |

7.5, 10.0 and 15.0mm |

| Power Rating |

1.2kW |

| Voltage |

3~400V/50Hz |

| Oil Flow |

3.6 l/min |

| Cycle time* |

11.5 sec. |

| Cycle time** (repeat operation) |

9.4 sec, |

| Minimum L-Bend |

25mm |

| Minimum U-Bend |

60mm |

| Minimum Z-Bend |

70mm |

* 90 Degree bend 120x10mm busbar size return stroke including

full automatic spring back compensation

** 90 Dgree bend 120 x 10mm busbar size repeat operation

|