| |

Busbar

Fabrication HSBL-2 Professional System 2 Busbar

Fabrication HSBL-2 Professional System 2 |

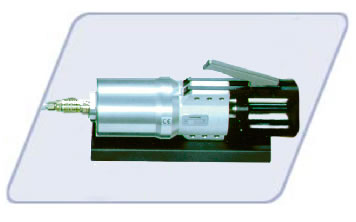

HSBL-Work Cylinder

The work cylinder is the central and essential point of the

Novopress HSBL-2 System. Operated with the various hydraulic

power packs, it is the key to perfect, simultaneous and efficient

busbar fabrication. The HA1 ES power pack offers maximum portability

whereas the HA 4 provides unsurpassed production output. Two

simple bolts transform the Novopress HSBL-2 System into a universal

cutting, punching or bending tool in no time.

Advantages at a Glance:

- Interchangeable cylinder for cutting / punching / bending

attachments.

- Quick and easy mounting bolts, no tools needed

- Production output scalable by use of multiple work-cylinders

and power packs

| Technical Specifications |

| Length |

615mm |

| Width |

140mm |

| Height |

340mm |

| Weight |

20Kg |

| Stroke |

120mm |

| Hydraulic Pressure |

150 bar max. (2200psi) |

| Max. Busbar Size |

120x13mm |

| Force |

150 kN |

| Suitable Power Packs |

HA1-ES, HA3 or HA4 |

The HSBL work cylinder is also available in several complete

busbar systems, including punching tool - cutting tool - bending

tool and power pack HA3 at very advantageous net prices.

For details please check out our "Complete Busbar Systems".

|

|

|

|

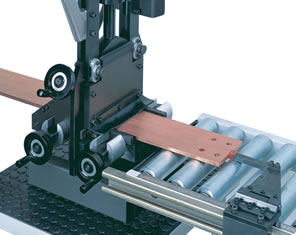

HSBL-Cutting Head

Two different cutting tools are available within

the HSBL-2 System. One up to 120x13 mm and as

shown on the picture, for 160x13 mm (6” x

1/2”) Of course with state of the art operator

safety and excellent cutting quality. Additional

accessories like fixing vice or conveyor systems

are available for professional stationary production.

| Technical Specifications |

| Width |

210mm |

| Height |

785mm |

| Weight |

9.6Kg |

| Cutting Performance |

160x13mm @ 250

Nmm2 |

*Picture shows cutting tool 160x13 mm (6”x1/2”)

including two fixing vices and conveyor.

Also Available:

Cutting Tool 120x13 mm

Cutting Tool 160x13 mm

Single Vice for 160x13mm Cutting Tool

Double Vice for 160x13mm Cutting Tool

|

|

|

|

HSBL-2 "DigiPunch 160"

- A New Class of Performance

With the brand-new ”DigiPunch 160”,

Novopress offers a new class of busbar punching

performance for medium- to large sized enterprises.

Wherever ordinary manual punches are insufficient

and CNC- controlled machines are to costly, the

new ”DigiPunch 160” is the ideal mid-size

solution. It reduces manufacturing time and cost

significantly compared to manual punches at a

very modest investment compared to CNC-punches.

The very practical configuration with digital

metering in X/Y axis and complete conveyors, enables

a very efficient and flexible busbar manufacturing.

Fast - Productive - Competitive

All necessary components except hydr. power pack

and work cylinder are included in delivery.

For operation only a regular 110V/60Hz or 220V/50Hz

power source is needed. The LCD measuring system

works on a permanent battery basis. Possible hydr.

Power Packs: HA1 ES, HA3 and HA4.

Advantages at a glance:

- Production volume up by 60%, compared to

manual HSBL-2 punches.

- Significantly reduced manufacturing costs.

- Optimised and speedy work flow through integrated

conveyor system and work-bench.

- No programming or preparatory work required,

very short set-up times.

- Fast and stepless positioning of busbars

in X and Y axis, with 0,5 mm accuracy.

- Switching from absolute to chain measurement

for fast and easy progressive punching.

| Technical Specifications |

| Overall Height |

1900mm |

| Width |

550mm |

| Length |

4300mm |

| Weight |

170Kg |

| Operating Pressure |

150 bar (2200psi) |

| Force |

150kN |

| Max. Busbar Size |

3000x160x13mm

(120"x6"x1/2") |

| Max. Measuring

Range |

2000x180mm |

| Measuing Accuracy |

0.5mm |

| Max.

Punch Size -Round |

21mm |

| Max. Punch Size

- Oblong |

21x14mm |

| Max. Punch Size

- Square |

12.5x12.5mm |

| Hydraulic Power

Packs |

HA1-ES, HA3,

HA4 |

|

|

|

|

New progressive punching dies:

Also the punching dies are new designed and further

reduce manufacturing cost. Punch and die are inter-

changeable by quick clamp mechanism within 20

sec. The solid tool holder enables progressive

punching for oblong and slotted wholes. Switching

from absolute to chain-measurement, offers fast

progressive punching without extra calculating.

Last but not least we offer a wide range of standard

dies for round- oblong- and square punching, especially

matched with the needs of the electrical industry.

- Solid dieholder for progressive punching of

oblong and slotted holes.

- Quick clamping offers fast and easy die change

within 20 seconds.

- Large assortment of standard dies for round-

oblong- and square punching.

- Set-up times are reduced, no tools necessary.

Also available as complete set, including punching

dies, HSBL-2 work cylinder and power pack HA3, at

very advantageous net prices.- Contact Us for More

information |

|

|

|

| |

|

|

|

|

|

|