| |

Introduction to Measurement Transformers

Measuring instruments, such as ammeters, voltmeters, kilowatt-hour

meters, etc , whether electromechanical or electronic, meet insuperable

design problems if faced with the high voltages or high currents

commonly used in power systems. Furthermore, the range of currents

employed throughout is such that it would not be practical to manufacture

instruments on a mass production scale to meet the wide variety

of current ranges required.

Current transformers are therefore used with the measuring instruments

to: (a) Isolate the instruments from the power circuits. (b) Standardise

the instruments, usually at 5 amps or 1 amp. The scale of the instrument

(according to the C T ratio), then becomes the only non-standard

feature of the instrument.

|

| |

Accuracy Class

Accuracy classes for various types of measurement are set out in

BSEN /IEC 60044-1. It will be seen that the class designation is

an approximate measure of the accuracy, e g , Class 1 current transformers

have ratio error within 1% of rated current. Phase difference is

important when power measurements are involved, i.e. when using

wattmeter's, kilowatt-hour meters, VAr meters and Power Factor meters.

|

|

| Class |

% current ratio at % of ratio current

shown below. |

Applications |

| 50 |

120 |

| 3 |

3 |

3 |

Ammeters |

| 5 |

5 |

5 |

Approximate Measurements |

|

| |

| Accuracy |

% current ratio error at % of rated

current shown below |

Phase displacement (minutes) at

% of rated current shown below |

Applications |

| Class |

5 |

20 |

100 |

120 |

5 |

20 |

100 |

120 |

| 0.1 |

0.4 |

0.2 |

0.1 |

0.1 |

15 |

8 |

5 |

5 |

Precision Testing & Measurement |

| 0.2 |

0.75 |

0.35 |

0.2 |

0.2 |

30 |

15 |

10 |

10 |

Precision Grade Meters |

| 0.5 |

1.5 |

0.75 |

0.5 |

0.5 |

90 |

45 |

30 |

30 |

Tarriff kWh Metering |

| 1.0 |

3.0 |

1.5 |

1.0 |

1.0 |

180 |

90 |

60 |

60 |

Commercial kWh Metering |

|

| |

The table below details limits of error for current transformers

for special applications and having a secondary current of 5A

|

| |

| Accuracy |

% current ratio error at % of rated

current shown below |

Phase displacement (minutes) at

% of rated current shown below |

| Class |

5 |

20 |

100 |

120 |

120 |

5 |

20 |

100 |

120 |

120 |

| 0.2s |

0.75 |

0.35 |

0.2 |

0.2 |

0.2 |

30 |

15 |

10 |

10 |

10 |

| 0.5s |

1.5 |

0.75 |

0.5 |

0.5 |

0.5 |

90 |

45 |

30 |

30 |

30 |

|

| |

|

|

|

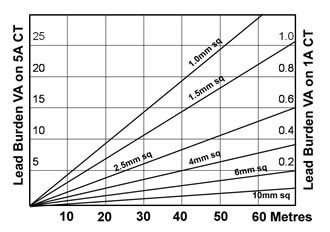

Meter & Pilot Lead Burden

Burden is the load imposed on the secondary of the CT at

rated current and is measured in VA (product of volts and

amps). The accuracy class applies only to loads at rated VA

and below, down to one quarter VA .The burden on the secondary

of a CT includes the effect of pilot leads, connections etc

, as well as the instrument burden itself.

In situations where the meter is remote from the current

transformer, the resistance of the pilot wires may exceed

the meter impedance many times in these cases it is often

economical to use 1 amp meters and CTs.

The diagram shows the burden imposed on the CT due to a run

of pilot wire. It will be seen that a pilot loop of 2.5mm2

wire, 60 metres long (30 metres distance) has a load of 12.5

VA on a 5 amp CT but only 0.5VA on a 1 amp CT.

|

|

|

| |

|

|

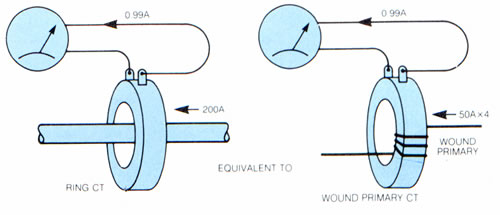

Wound Primary CTs

Thus, current transformers for 80 amps and

below frequently require more than 1 turn to achieve the desired

accuracy class. Considering again the previous example.

Using the same core and by winding 200 secondary turns and

4 primary turns a 50/1 ratio is achieved. The magnetising

ampere turns

remains at 2 as before, however the magnetising current becomes

2 divided by 4 turns or 0.5A and the percentage error is reduced

to 1% (approx.).

It is therefore possible to achieve accuracy requirements,

without using expensive core materials, by constructing a

wound primary transformer. Of course, the cost of the primary

winding with its insulation and terminations must be weighed

against the cost of the more expensive core which would be

required to achieve a 1% accuracy for a ring CT at a 50/1

ratio.

|

Ampere Turns Rule

An ideal transformer is based on the Amperre Turns Rule,

i.e. Primary Ampere Turns = Secondary Ampere Turns or: IpTp

= IsTs (Ts/Tp=Ip/Is)

Thus the current transformation ins in INVERSE proportion

to turns whereas voltage transformersion is in DIRECT proportion

to turns ie Ts/Tp=Vs/Vp

|

Design Considerations

As in all transformers, errors arise due to a proportion

of the primary input current being used to magnetise the core

and not transferred to the secondary winding. The proportion

of the primary current used for this purpose determines the

amount of error.

The essence of good design of measuring current transformers

is to ensure that the magnetising current is low enough to

ensure that the error specified for the accuracy class is

not exceeded.

This is achieved by selecting suitable core materials and

the appropriate cross-sectional area of core. Frequently in

measuring currents of 50A and upwards, it is convenient and

technically sound for the primary winding of a CT to have

one turn only.

In these most common cases the CT is supplied with a secondary

winding only, the primary being the cable or busbar of the

main conductor which is passed through the CT aperture in

the case of ring CTs (i .e. single primary turn) it should

be noted that the lower the rated primary current the more

difficult it is (and the more

expensive it is) to achieve a given accuracy.

Considering a core of certain fixed dimensions and magnetic

materials with a secondary

winding of say 200 turns (current ratio 200/1 turns ratio

1/200) and say it takes 2 amperes of the 200A primary current

to magnetise the core, the error is therefore only 1% approximately.

However considering a 50/1 CT with 50

secondary turns on the same core it still takes

2 amperes to magnetise to core. The error is then 4% approximately.

To obtain a 1%

accuracy on the 50/1 ring CT a much larger core and/or expensive

core material is required.

|

Saturation

Magnetic materials are such that when the magnetic flux reaches

a certain value the core will saturate. At this point a large

proportion of the primary current is required to magnetise

the core Increasing the primary current in the saturation

region will therefore cause only a marginal increase in secondary

current. It is obvious that the CT is completely inaccurate

when saturated Saturation can occur if the actual burden exceeds

the rated burden, or if heavy overcurrents occur.

This phenomenon can be used to protect an instrument against

damage due to heavy overcurrent and a Saturation Factor is

sometimes specified. For example, if a Instrument Sensitivity

Factor (Fs) of less than 5 is specified, the CT must be designed

to ensure that, at the rated burden, the core is well into

the saturation region (defined point) at 51 times the rated

primary

current.

It is critical that the actual burden is established to ensure

the saturation factor is complied with. Fs is the ration of

instrument limit primary current to the rated primary current.

The lower the factor the higher the degree of safety. However

it is not always practical to achieve a high accuracy class

with an extremely low instrument security factor.

|

Open Circuit Current Transformers

It is important to ensure that the secondary of any CT is

not left disconnected while the primary supply is on. In this

condition, high voltage spikes are produced in the transformer

secondary, often thousands of volts, sufficient to break down

the transformer insulation.

|

| |

Dual or Multi-Ratio Transformers

Frequently when a new plant is commissioned, it is planned

for further extension and consequent increase in power consumption.

In this event, it may be advisable to install dual ratio CTs

with a tapped secondary to allow alterations to the metering

without the expense and disruption of replacing the CTs. In

this case, the unused terminal should be left open-circuit.

|

Construction of Measuring Current Transformers

Measuring current transformers are available in a variety

of different forms and terminations to meet the requirements

of the particular installation.

Taped Ring CTs

(R Range)

Suitable for Indoor use, are probably the most common type

of CT Installed in LV switchgear and control gear Circular

cores wound in clock spring fashion provide a near ideal magnetic

circuit, free of air gaps and having very low leakage or stray

fields. After applying suitable robust insulation to these

cores, the windings are applied evenly around the cores by

toroidal winding

machines. Taped ring CTs are a so used extensively in HV switchgear

and power transformers where the insulation is provided by

the HV bushings. Where CTs are to be installed under hot oil,

insulation materials have to be selected to avoid pollution

of the oil. Rectangular core CTs are also available to suit

applications where space is very restricted.

Enclosed Plastic Moulded Case

Current Transformers (M Range)

Similar to the ring CTs but enclosed in tough injection moulded

shells to provide a clean and uniform appearance. Mounting

brackets and facilities for busbar clamps and other accessories

can be incorporated in the mould design thereby resulting

in a lower cost unit. The speed and simplicity with which

moulded case CTs can be clamped to busbars is an important

feature of the unit.

|

Legacy

Model MT0 - Discontinued

|

Legacy Model MWBD -

Contact us for

more information |

|

|

Legacy

Model MT21 - Discontinued

|

|

|

|

Legacy Model MT33 - Discontinued

|

|

|

|

Legacy

Model M4085 - Discontinued

|

Legacy

Model MT53 - Discontinued

|

Legacy

Model MT61 - Discontinued

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Resin Cast Current Transformer

Produced by casting the transformer in liquid resin which

is then cured to the solid state. These transformers are expensive,

but they are robust and immune to difficult climatic conditions.

Special resins are now available to make the transformers

suitable for outdoor use. Resin Cast CTs are commonly used

at high voltages, up to 33kV. In these applications, highly

controlled casting techniques are required to avoid air voids

where corona discharge could effect the quality of insulation.

|

| |

|

|

|

| |

|

| |

|

| |

|

|